What is Thermal Break Aluminum? Basic Principles of Thermal Break Aluminum Windows and Doors

1.What is Thermal Break Aluminum?

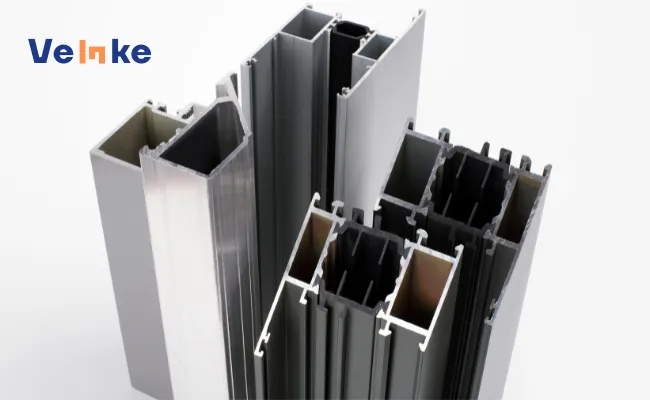

Thermal Break Aluminum is a composite profile that incorporates thermal barriers (typically made of nylon or polyurethane materials) within aluminum profiles through special manufacturing processes. This design creates a "thermal break" within the aluminum profile, effectively blocking heat conduction paths and significantly improving the thermal insulation performance of windows and doors.

—— Basic Principles of Thermal Break Technology

The thermal break principle is based on the fundamental concept of interrupting thermal bridges. In traditional aluminum windows, heat flows directly through the metal frame, creating a thermal bridge that allows significant heat transfer. Thermal break technology introduces a low-conductivity material between the inner and outer aluminum sections, creating a barrier that dramatically reduces heat flow.

Technical Characteristics

| Characteristic | Traditional Aluminum | Thermal Break Aluminum | Improvement |

|---|---|---|---|

| Thermal Conductivity | 160-200 W/m·K | 0.2-0.3 W/m·K | 99.8% reduction |

| U-Value | 5.0-6.0 W/m²·K | 1.2-2.0 W/m²·K | 60-75% improvement |

| Energy Efficiency | Low | High | Significant improvement |

| Condensation Risk | High | Low | 80% reduction |

| Sound Insulation | 25-30 dB | 35-45 dB | 30-50% improvement |

2.Manufacturing Process

The production of thermal break aluminum involves several critical steps:

- Profile Extrusion: Aluminum profiles are extruded to specific dimensions

- Thermal Barrier Insertion: Insulating materials are inserted into the profile channels

- Mechanical Connection: Inner and outer aluminum sections are mechanically connected

- Quality Control: Comprehensive testing ensures structural integrity and thermal performance

The production of thermal break aluminum represents a sophisticated manufacturing process that combines precision engineering with advanced materials science. This multi-stage operation begins with the careful selection and preparation of raw materials, where high-quality aluminum billets are sourced and inspected for purity and consistency. The manufacturing process involves several critical phases, each designed to ensure optimal performance and structural integrity.

The first stage involves profile extrusion, where aluminum billets are heated to approximately 480-520°C and forced through precision dies to create the desired cross-sectional shapes. This process requires meticulous temperature control and pressure management to achieve the exact dimensions and surface quality specifications. The extruded profiles are then rapidly cooled using controlled quenching systems to maintain the desired metallurgical properties.

Following extrusion, the profiles undergo a critical thermal break insertion process. This involves carefully positioning high-performance insulating materials, typically nylon 66 reinforced with glass fibers, into the designated channels within the aluminum profiles. The thermal barriers are precisely cut and shaped to fit the specific profile geometry, ensuring a perfect mechanical connection between the inner and outer aluminum sections.The mechanical connection phase represents one of the most critical aspects of the manufacturing process.

Specialized equipment is used to create a strong, durable bond between the aluminum sections and the thermal barrier. This process involves controlled pressure application and may include additional mechanical fastening methods to ensure long-term structural integrity under various environmental conditions.Quality control is integrated throughout the entire manufacturing process, with continuous monitoring of dimensional accuracy, surface finish, and material properties.

Performance Advantages

1. Thermal Insulation

- U-Value: Typically ranges from 1.2 to 2.0 W/m²·K

- Energy Savings: Can reduce heating and cooling costs by 20-30%

- Comfort: Maintains consistent indoor temperatures

2. Sound Insulation

- STC Rating: 35-45 decibels

- Noise Reduction: Effective barrier against external noise

- Acoustic Comfort: Creates quieter indoor environments

3. Structural Integrity

- Strength: Maintains aluminum's structural properties

- Durability: Long-lasting performance with minimal maintenance

- Weather Resistance: Excellent resistance to environmental factors

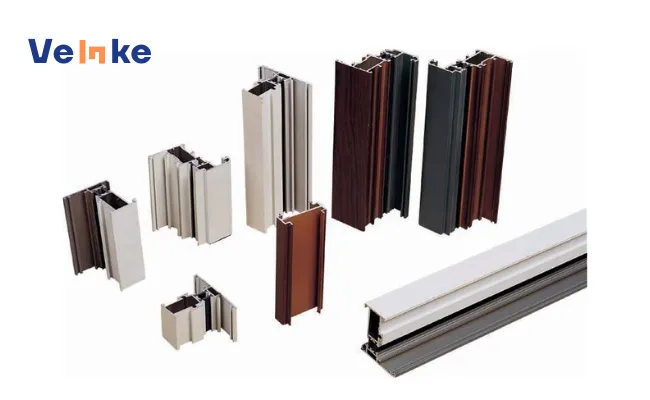

Material Composition

| Component | Material | Percentage | Function |

|---|---|---|---|

| Outer Frame | Aluminum 6063-T5 | 45-50% | Structural support, weather resistance |

| Inner Frame | Aluminum 6063-T5 | 45-50% | Structural support, interior finish |

| Thermal Barrier | Nylon 66 + Glass Fiber | 5-10% | Thermal insulation, structural connection |

| Coating | Powder Coating | <1% | Corrosion protection, aesthetics |

Installation Considerations

Pre-Installation Requirements

- Opening Preparation: Ensure proper dimensions and squareness

- Weather Barrier: Install appropriate weatherproofing

- Structural Support: Verify adequate load-bearing capacity

Installation Process

- Frame Positioning: Accurate placement and leveling

- Anchoring: Secure attachment to building structure

- Glazing: Proper glass installation and sealing

- Hardware: Installation of operating mechanisms

- Sealing: Application of weatherproofing materials

3.Quality Standards and Testing

International Standards

- EN 14351-1: European standard for windows and doors

- ASTM E283: Air leakage testing

- ASTM E331: Water penetration testing

- ASTM E330: Structural performance testing

Performance Testing

| Test Type | Standard | Typical Results |

|---|---|---|

| Air Leakage | ASTM E283 | <0.1 cfm/ft² |

| Water Penetration | ASTM E331 | No leakage at 15 psf |

| Structural Load | ASTM E330 | Passes 1.5x design load |

| Thermal Performance | ASTM C1363 | U-value as specified |

Cost-Benefit Analysis

Initial Investment

- Material Cost: 30-50% higher than standard aluminum

- Installation Cost: 20-30% higher due to complexity

- Total Premium: 25-40% over conventional windows

Long-term Benefits

- Energy Savings: $200-500 annually per window

- Maintenance: 50% reduction in maintenance costs

- Lifespan: 25-30 years vs. 15-20 years for standard aluminum

- ROI: 3-5 year payback period

Application Scenarios

Residential Applications

- Single-family Homes: Primary windows and doors

- Condominiums: Balcony doors and windows

- Townhouses: Energy-efficient upgrades

Commercial Applications

- Office Buildings: Curtain wall systems

- Retail Spaces: Storefront windows

- Healthcare Facilities: Specialized performance requirements

Climate Considerations

| Climate Zone | U-Value Requirement | Thermal Break Suitability |

|---|---|---|

| Hot Humid | 2.0-3.0 W/m²·K | High |

| Mixed Humid | 1.5-2.5 W/m²·K | Very High |

| Cold | 1.0-2.0 W/m²·K | Essential |

| Very Cold | 0.8-1.5 W/m²·K | Critical |

4.Maintenance and Care

Regular Maintenance

- Cleaning: Monthly cleaning with mild detergent

- Hardware: Annual lubrication of moving parts

- Seals: Inspection and replacement every 5-7 years

- Coating: Touch-up as needed

Troubleshooting Common Issues

| Issue | Cause | Solution |

|---|---|---|

| Condensation | Poor thermal break | Verify installation quality |

| Air Leakage | Worn seals | Replace weatherstripping |

| Difficult Operation | Hardware issues | Lubricate or replace hardware |

| Visual Defects | Coating damage | Professional refinishing |

Thermal Break Aluminum represents a sophisticated solution to the thermal performance challenges of aluminum windows and doors. Through innovative design and advanced manufacturing techniques, it provides superior energy efficiency, comfort, and durability while maintaining the structural benefits of aluminum. As energy efficiency requirements continue to tighten globally, thermal break aluminum will play an increasingly important role in sustainable building design.The investment in thermal break aluminum windows and doors pays dividends through reduced energy costs, improved comfort, and enhanced property value. For architects, builders, and homeowners seeking optimal performance, thermal break aluminum offers the perfect balance of functionality, aesthetics, and sustainability.

Ready to partner with a construction company that can deliver globally? Contact us today to discuss your construction needs and discover how we can bring Chinese manufacturing

📞 DM Us Consultation Services

Need professional guidance? Our team of commercial door experts is available to help you make the right choice:

- Free Consultation: Initial assessment and recommendations

- Technical Support: Detailed specifications and requirements

- Installation Services: Professional installation and testing

- Maintenance Programs: Ongoing support and maintenance

Contact us today to schedule your free commercial door consultation and ensure your project's success!