How to Source Quality Aluminum Windows at Wholesale Prices

Sourcing high-quality aluminum windows at competitive wholesale prices is crucial for contractors, builders, and wholesalers looking to maximize their profit margins while delivering superior products to their clients.

The aluminum window market offers numerous options, but identifying reliable suppliers and negotiating favorable terms requires strategic planning and industry knowledge. This page provides some strategies for sourcing quality aluminum windows that meet your specifications and budget requirements.

1.Understanding Aluminum Window Quality Standards

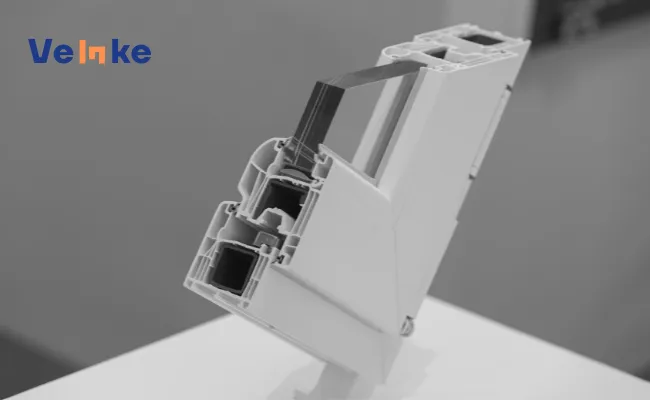

Quality aluminum windows are defined by several key factors including material composition, manufacturing processes, and performance certifications. Understanding these standards will help you evaluate suppliers and ensure you're sourcing products that meet industry requirements and client expectations.

Key Quality Indicators:

- Aluminum alloy composition (typically 6063-T5 or 6061-T6)

- Thermal break technology

- Weather sealing systems

- Hardware quality

- Finish durability

- Energy performance ratings

2.Supplier Research and Evaluation

Identifying Potential Suppliers

Finding reliable aluminum window suppliers requires comprehensive research across multiple channels. Start with industry directories, trade associations, and referrals from industry professionals.Research Channels:

- Industry trade directories

- Trade association memberships

- Professional referrals

- Trade show exhibitions

- Online supplier platforms

- Manufacturer websites

Supplier Evaluation Criteria

When evaluating potential suppliers, consider multiple factors beyond just pricing. Quality, reliability, and service capabilities are equally important for long-term success.Evaluation Matrix:

| Criteria | Weight | Description |

|---|---|---|

| Product Quality | 30% | Material standards, certifications, testing |

| Pricing Competitiveness | 25% | Wholesale rates, volume discounts |

| Delivery Reliability | 20% | On-time delivery, order accuracy |

| Technical Support | 15% | Engineering assistance, specifications |

| Payment Terms | 10% | Credit terms, payment flexibility |

3.Negotiating Wholesale Pricing

Understanding Pricing Structures

Aluminum window pricing is influenced by multiple factors including material costs, manufacturing complexity, order volume, and market conditions. Understanding these factors will help you negotiate better terms.

Pricing Components:

- Raw material costs

- Manufacturing overhead

- Labor costs

- Transportation

- Profit margins

- Market demand

Volume Discount Strategies

Larger order volumes typically result in better pricing per unit. Plan your purchasing strategy to maximize volume discounts while managing inventory costs.Volume Discount Tiers:

| Annual Volume | Discount Range | Additional Benefits |

|---|---|---|

| $100K - $500K | 5-10% | Standard terms |

| $500K - $1M | 10-15% | Extended payment terms |

| $1M - $2M | 15-20% | Priority production |

| $2M+ | 20%+ | Custom pricing, dedicated support |

4.Quality Assurance and Testing

Material Certification Requirements

Ensure your suppliers provide proper material certifications and testing documentation. This protects you from quality issues and helps with project specifications.Required Certifications Table

| Certification Type | Purpose | Scope | Validity Period | Verification Method |

|---|---|---|---|---|

| ASTM Standards Compliance | Material and performance testing standards | Material properties, dimensional accuracy, durability testing | Annual renewal | Third-party testing reports, certification documents |

| AAMA Ratings | Architectural performance standards | Air infiltration, water resistance, structural performance | 5 years | AAMA testing and certification, performance ratings |

| Energy Star Certification | Energy efficiency compliance | Thermal performance, U-factor, SHGC ratings | 3 years | Energy Star testing, certification labels |

| Local Building Code Compliance | Regulatory compliance | Fire safety, structural requirements, accessibility | Varies by jurisdiction | Code compliance certificates, inspection reports |

| ISO Quality Management Systems | Quality management processes | Manufacturing processes, quality control, continuous improvement | 3 years | ISO 9001 certification, audit reports, management system documentation |

Quality Control Procedures

Implement quality control procedures to verify product quality upon delivery and identify issues before they reach your customers.

QC Checklist:

- Visual inspection for defects

- Dimensional accuracy verification

- Hardware functionality testing

- Finish quality assessment

- Packaging integrity check

5.Building Long-term Supplier Relationships

Partnership Development

Strong supplier relationships provide benefits beyond competitive pricing, including priority production, technical support, and market intelligence.

Relationship Building Strategies:

- Regular communication

- Joint planning sessions

- Performance reviews

- Collaborative improvement projects

- Market information sharing

Contract Negotiation

Well-structured contracts protect both parties and establish clear expectations for quality, delivery, and service.

Contract Elements Table

| Contract Element | Description | Key Considerations |

|---|---|---|

| Quality Specifications | Detailed technical requirements and performance standards | Material composition, dimensional tolerances, finish requirements, performance criteria |

| Delivery Terms | Shipping, delivery schedules, and logistics arrangements | Delivery dates, shipping methods, incoterms, packaging requirements, delivery locations |

| Payment Conditions | Payment terms, methods, and schedules | Payment due dates, accepted payment methods, late payment penalties, advance payment requirements |

| Warranty Provisions | Product warranty coverage and terms | Warranty duration, coverage scope, exclusions, claim procedures, repair/replacement policies |

| Dispute Resolution | Procedures for handling disagreements | Mediation processes, arbitration clauses, governing law, jurisdiction, escalation procedures |

| Termination Clauses | Conditions and procedures for contract termination | Notice periods, termination reasons, penalty clauses, transition arrangements, final settlement |

6.Supply Chain Optimization

Logistics and Transportation

Efficient logistics management reduces costs and ensures timely delivery. Consider factors such as shipping methods, consolidation opportunities, and regional distribution.

Logistics Considerations:

- Shipping method selection

- Consolidation opportunities

- Regional distribution centers

- Delivery scheduling

- Damage prevention

Inventory Management

Balancing inventory levels with demand patterns helps minimize carrying costs while ensuring product availability.

Inventory Strategies:

- Just-in-time ordering

- Safety stock levels

- Seasonal adjustments

- Product lifecycle management

- Storage optimization

Successfully sourcing quality aluminum windows at wholesale prices requires a strategic approach combining thorough research, effective negotiation, and strong supplier relationships. By following these guidelines and continuously monitoring market conditions, you can establish reliable supply chains that support your business growth and profitability.

Remember that the lowest price isn't always the best value. Focus on finding suppliers who offer the right combination of quality, service, and competitive pricing to meet your long-term business objectives.

📞 DM Us Consultation Services

Need professional guidance? Our team of commercial door experts is available to help you make the right choice:

- Free Consultation: Initial assessment and recommendations

- Technical Support: Detailed specifications and requirements

- Installation Services: Professional installation and testing

- Maintenance Programs: Ongoing support and maintenance

Contact us today to schedule your free commercial door consultation and ensure your project's success!