Best Window Types Comparison: Aluminum vs Other Materials

When choosing windows for your home or commercial building, the material selection plays a crucial role in determining performance, durability, and aesthetics. This comprehensive comparison will help you understand the key differences between aluminum windows and other popular materials.

Material Properties Comparison

| Property | Aluminum | Vinyl | Wood | Fiberglass | Steel |

|---|---|---|---|---|---|

| Durability | Excellent | Good | Moderate | Excellent | Excellent |

| Maintenance | Low | Very Low | High | Low | Moderate |

| Energy Efficiency | Good | Excellent | Good | Excellent | Poor |

| Cost | Moderate-High | Low-Moderate | High | High | Moderate |

| Lifespan | 20-30 years | 20-25 years | 15-25 years | 25-30 years | 20-30 years |

| Weather Resistance | Excellent | Good | Moderate | Excellent | Good |

| Design Flexibility | High | Moderate | High | High | Moderate |

Manufacturing Process & Technology

Aluminum Windows

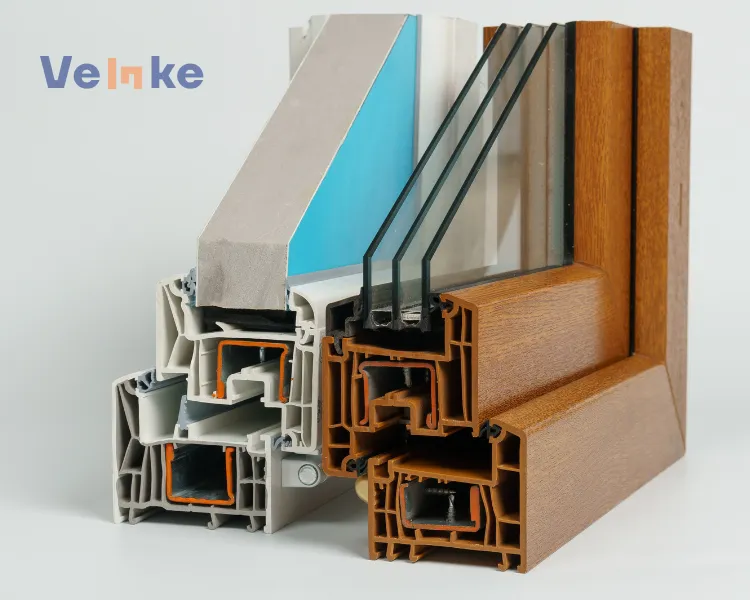

The manufacturing of aluminum windows begins with the extrusion process, where aluminum billets are heated to temperatures between 450-500°C and forced through precision-engineered dies under high pressure. This process creates the complex profile shapes that define modern aluminum window systems. After extrusion, the profiles undergo air cooling and stretching to achieve optimal dimensional stability.

The final stages involve precision cutting, machining for hardware attachment points, and surface treatment through either anodizing or powder coating processes. Advanced thermal break technology is integrated during assembly, where polyamide strips are mechanically fastened between inner and outer aluminum profiles to prevent thermal bridging.

Multi-chamber designs are incorporated to enhance structural integrity and provide additional thermal insulation. The entire process emphasizes tight tolerances and quality control, with modern facilities utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to ensure consistency across production runs.

Extrusion Process:

- Billet heating to 450-500°C

- High-pressure extrusion through dies

- Air cooling and stretching

- Precision cutting and machining

- Surface treatment (anodizing/powder coating)

Advanced Technologies:

- Thermal break technology for improved insulation

- Multi-chamber profiles for enhanced structural integrity

- Powder coating with UV resistance

- Precision engineering for tight tolerances

Vinyl Windows

Injection Molding:

- PVC compound preparation

- High-temperature injection molding

- Cooling and solidification

- Quality inspection and assembly

Key Features:

- Multi-chamber design for thermal efficiency

- UV-stabilized compounds

- Welded corner joints for strength

Wood Windows

Traditional Craftsmanship:

- Kiln-dried lumber selection

- Precision cutting and joinery

- Hand-finished surfaces

- Multiple coating applications

Modern Enhancements:

- Engineered wood components

- Advanced sealant technology

- Weather-resistant treatments

Performance Analysis

Thermal Performance

- Aluminum: U-value 1.8-2.2 W/m²K (with thermal breaks)

- Vinyl: U-value 1.2-1.8 W/m²K

- Wood: U-value 1.4-2.0 W/m²K

- Fiberglass: U-value 1.2-1.6 W/m²K

When evaluating window performance, several key metrics provide comprehensive insights into material effectiveness. Thermal performance, measured by U-value (heat transfer coefficient), reveals that aluminum windows typically achieve U-values between 1.8-2.2 W/m²K when equipped with thermal breaks, while vinyl windows excel with values of 1.2-1.8 W/m²K. Sound insulation capabilities show aluminum windows providing 35-40 dB reduction, comparable to wood and fiberglass options but superior to basic vinyl systems.

Structural performance demonstrates aluminum's exceptional strength-to-weight ratio, capable of supporting larger glass panes and maintaining dimensional stability under extreme weather conditions. Long-term durability assessments indicate aluminum windows maintain their performance characteristics for 20-30 years with minimal maintenance, while weathering resistance tests confirm their ability to withstand UV exposure, temperature fluctuations, and environmental pollutants without degradation.

Energy efficiency ratings, particularly important for building code compliance and sustainability goals, show that modern aluminum systems with thermal breaks can achieve ENERGY STAR® certification, making them competitive with other high-performance materials in the market.

Sound Insulation

- Aluminum: 35-40 dB reduction

- Vinyl: 30-35 dB reduction

- Wood: 35-40 dB reduction

- Fiberglass: 35-40 dB reduction

Cost-Benefit Analysis

| Material | Initial Cost | Maintenance Cost | Long-term Value | ROI |

|---|---|---|---|---|

| Aluminum | $400-800 | $50-100/year | High | 85-90% |

| Vinyl | $200-500 | $20-50/year | Moderate | 75-80% |

| Wood | $600-1200 | $150-300/year | High | 80-85% |

| Fiberglass | $500-1000 | $30-80/year | High | 85-90% |

Environmental Impact

Sustainability Factors

- Aluminum: 100% recyclable, low carbon footprint

- Vinyl: Recyclable but limited end-of-life options

- Wood: Renewable resource, carbon sequestration

- Fiberglass: Energy-intensive production, limited recycling

Energy Efficiency Ratings

- Aluminum: ENERGY STAR® certified options available

- Vinyl: Excellent thermal performance

- Wood: Natural insulating properties

- Fiberglass: Superior thermal efficiency

Installation Considerations

Installation Complexity

- Vinyl: Easiest (DIY-friendly)

- Aluminum: Moderate (professional recommended)

- Wood: Complex (professional required)

- Fiberglass: Moderate (professional recommended)

The installation of aluminum windows requires careful attention to detail and professional expertise due to their precision-engineered nature. Unlike vinyl windows which offer more flexibility during installation, aluminum systems demand proper flashing installation, precise leveling, and meticulous sealing procedures to prevent water infiltration and air leakage. The installation process typically involves setting the window frame with shims for perfect alignment, applying appropriate sealants and weatherstripping, and ensuring proper integration with the building's moisture barrier system.

Site preparation is crucial, as aluminum windows require adequate structural support and proper rough opening dimensions. Professional installation is strongly recommended for aluminum windows to ensure optimal performance, warranty compliance, and long-term durability. The installation complexity varies based on the specific aluminum system chosen, with commercial-grade systems requiring more sophisticated installation techniques compared to residential applications.

Site Requirements

- Aluminum: Requires proper flashing and sealing

- Vinyl: Flexible installation options

- Wood: Moisture protection critical

- Fiberglass: Standard installation procedures

Maintenance Requirements

Annual Maintenance Tasks

- Aluminum: Clean frames, check seals, lubricate hardware

- Vinyl: Wash surfaces, inspect seals, clean tracks

- Wood: Refinish surfaces, check for rot, maintain seals

- Fiberglass: Clean frames, inspect seals, check hardware

Aluminum windows require relatively low maintenance compared to other materials, making them an attractive choice for commercial and residential applications. The primary maintenance tasks include regular cleaning of frame surfaces using mild soap and water solutions, inspection and replacement of weatherstripping when necessary, and lubrication of moving hardware components such as hinges and locks.

Annual inspections should focus on checking seal integrity, ensuring proper drainage through weep holes, and verifying that thermal breaks remain intact. Unlike wood windows that require periodic refinishing, aluminum frames maintain their appearance with minimal effort. However, it's essential to address any scratches or damage to the powder coating promptly to prevent corrosion. The maintenance schedule typically involves quarterly cleaning and annual comprehensive inspections, with professional assessment recommended every 3-5 years to identify potential issues before they become significant problems.

Aluminum windows offer an excellent balance of durability, design flexibility, and performance. While they may have a higher initial cost compared to vinyl, their longevity and low maintenance requirements make them a cost-effective choice for commercial and high-end residential applications.For optimal results, consider:

- Local climate conditions

- Building design requirements

- Budget constraints

- Long-term maintenance capabilities

- Environmental impact preferences

Choose the material that best aligns with your specific needs, budget, and aesthetic preferences.